|

||||||||

Jim Rylatt (pictured above from the recent flint identifying workshop) has graciously completed a report for WAG on the flint axe head and discoidal knife that were found near Pear Tree Farm. The report is below. |

||||||||

Pear Tree Farm, Washingborough Fen, Lincolnshire Assessment of Flint Axe & Knife Report by Jim Rylatt – October 2005 © 1.0 Introduction This report relates to a polished flint axe and a discoidal knife that were discovered c. 1975, on land belonging to Pear Tree Farm (vicinity of TF 0382 7088). These artefacts are in the possession of the finder and were not available for examination, but a series of high definition photographs of the objects have been assessed and the results presented in this report are based on characteristics evident in these images. The nature of this analysis means that the results are only provisional and would probably be amended if the stone tools were made available for physical examination. 2.0 Catalogue 2.1 Flint Axe |

||||||||

| ||||||||

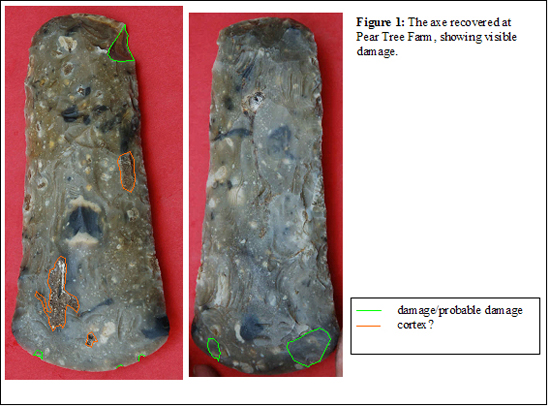

Typological classification: Edge-ground, thin-butted (type B) with concave sides and lenticular (double-convex) cross-section. This axe blade is virtually complete and appears to have little or no post-deposition recortication. It is roughly quadrilateral in profile. The butt end has a slightly convex squared outline and forms the narrowest part of the axe. The lateral edges are slightly concave, with the blade becoming progressively wider toward the cutting edge. The cutting edge itself is the broadest part of the tool and is markedly convex. It differs from the other three edges of the blade, because it has been ground and polished. This polish extends approximately a quarter of the way up the blade; it has almost totally removed the flake scars within 15 mm of the cutting edge, and more limited grinding along the central axis of the blade has partially removed scar facets located up to 40 mm from the cutting edge. The limited extent of the polish suggests that the axe blade was ground primarily to increase its functional effectiveness. Prior to grinding, each of the numerous facets along the cutting edge would have acted as platforms that could potentially have redirected impact forces when the axe was in use - this could either have detached irregular invasive flakes from the cutting edge or even have made the blade shatter. Grinding would have made the axe more resistant to this sort of damage. The other three edges have been shaped and dressed but are otherwise unmodified. Large multi-directional flake scars are visible toward the centre of both faces of the axe blade; these were created during the thinning and shaping of the preform. Subsequently, a series of much smaller, overlapping flakes were removed along the lateral and upper edges. The side views indicate that these flakes extend along the upper 110 mm of the blade, which creates distinctly serrated or ‘crimped’ margin. This morphological trait makes it possible to determine the sequence of flake removal for this final dressing of the tool – each of these small flakes was removed from the alternate side to the previous removal. The pronounced negative bulb suggests that a stone hammer was used for this dressing. If so, the fine control exhibited would suggest a thin ovate pebble, but alternatively, it is possible that a relatively heavy piece of antler (soft hammer) was utilised. The axe exhibits some evidence of damage (fig. 1). Two flakes, one small and the other medium-sized, have been detached from the cutting edge (there is also a small nick in the cutting edge). These flakes are acute to semi-abrupt removals, which suggest that they were detached while the axe was in use. A more abrupt flake has detached from the junction between the butt end and one lateral edge. This flake is more likely to reflect some form of post-depositional damage, such as plough damage. The overall effect of post-depositional processes on the condition of the piece could only be accessed by a physical examination. The axe appears to have been made from a nodule of greyish caramel-brown opaque flint that has a high density of dark grey and small ‘bubbly’ chalky inclusions. There are some small areas of irregular chalky cortex on one side of the axe blade (fig. 1), but it is not clear whether these represent small voids and imperfections within the nodule, or if they are elements of the original outer surface of the core. On balance, the latter seems more likely, suggesting that the core was a large oval pebble extracted from gravel deposits (i.e. secondary sources).  2.2 Discoidal Knife |

||||||||

| ||||||||

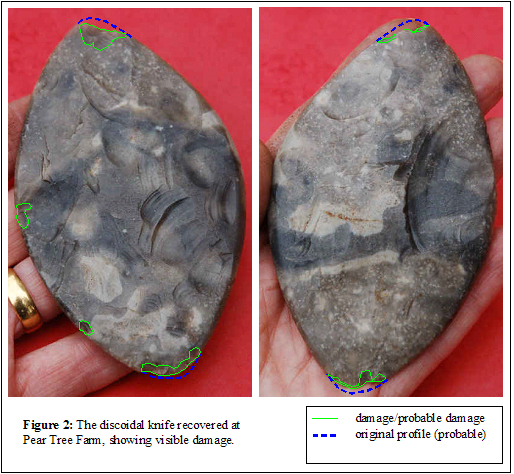

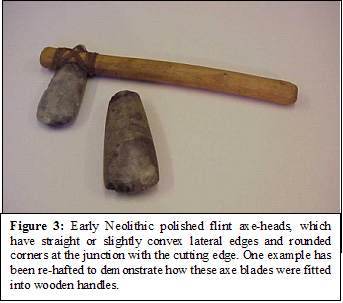

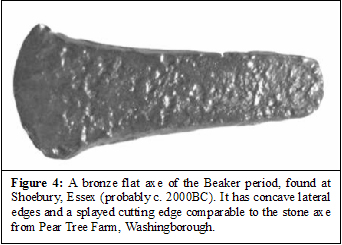

Typological classification: Class III – lozenge-shaped with ground edges (Clarke, 1932). This knife has some damage to the tip of both ends and there is slight post-deposition recortication (patination). It has been manufactured on a large flat flake that has had the platform and bulb removed. The flake was bifacially worked over its entire surface to create a relatively symmetrical biconvex profile, although one edge has a slightly greater curvature than the other. After the desired shape had been formed, the entire margin of the knife was ground. Like the knapping, this grinding was performed around the perimeter of both faces of the flake and created a bevelled edge with an angle of c. 60° between the two surfaces. The images suggest that there was a difference in the quality of the ground finish along the two edges. The more rounded edge appears to be carefully polished, with a slightly wider bevelled edge that is probably sharper than the flatter margin - the latter appears to be more irregular, and has a somewhat rounded junction between the two ground faces that is probably fairly blunt. However, it is possible that neither edge was truly sharp, as a significant proportion of ground-edge discoidal knives are relatively blunt, suggesting that they were designed to be used as a form of multi-purpose tool rather than as a sharp knife purely for cutting (Butler 2005). Both surfaces of the knife have also been ground, but this has only served to remove the more prominent elements of the flake scar ridges. There is some suggestion that the grinding was more concerted on one side than the other (fig. 2: the right hand image looks smoother), but this could only be confirmed by a physical examination. Part of the reason for the removal of the flake scar ridges may have been for aesthetic enhancement, but it is likely that the primary purpose was to make the tool easier to handle and less likely to lacerate the user. The discoidal knife exhibits evidence of some damage and slight truncation at both ends (fig. 2). The removal of the tips is probably due to post-depositional processes, such as plough damage, as these are the narrowest and most vulnerable areas of the tool. However, the possibility that the tips were detached during use of the tool should also be considered. Two very small, semi-abrupt flakes that have been detached from the slightly flatter edge probably reflect some form of post-depositional damage. The overall effect of post-depositional processes on the condition of the piece can only be accessed by a physical examination. The knife appears to have been made from a nodule of mottled pale grey to pale brownish-grey opaque flint that has a high density of dark grey and small ‘bubbly’ chalky inclusions. There does not appear to be any cortex surviving on the surface of the knife (fig. 1). Nonetheless, the composition of the flint indicates that it is more likely that the parent core was obtained from secondary deposits, such as gravel beds, than from a mine. 3.0 Discussion 3.1 Dating The morphological characteristics of the axe blade provide a clear indication that it was manufactured during the late Neolithic. The shape of earlier Neolithic axes is significantly different, as they generally range from straight-sided to teardrop-shaped, and furthermore, they tend to have rounded corners at the junction between the lateral edges and the cutting edge (fig. 3). In contrast, the axe found at Pear Tree Farm has concave lateral edges and a splayed, convex cutting edge, which are features of the latest stone axes created toward the very end of the Neolithic. In fact these same attributes were also copied by the makers of the earliest copper and bronze flat axes that were manufactured in the first half of the Beaker period (fig. 4); Beaker is a term given to a period of time spanning the later Neolithic to the early Bronze Age - c. 2700BC-1700 BC (Parker-Pearson 1993). Copper axes were first introduced to Britain c. 2300BC, with the early Bronze Age beginning c. 2200BC. Therefore, a date range of 2400-2200BC represents the period during which the Pear Tree Farm axe was probably manufactured. Discoidal knives are almost exclusively of late Neolithic date, although one or two examples have been found in middle Neolithic deposits (e.g. Clark 1960). When recovered from stratified contexts they are often found in association with Grooved Ware pottery, the various sub-types of Grooved Ware vessels having been in circulation between c. 3100 and 2600BC (Garwood 1999). In Britain the late Neolithic phase began c. 3000BC, which suggests that the discoidal knife from Pear Tree Farm was manufactured between 3000 and 2600BC. Although the axe and the knife are both considered to be late Neolithic objects, there no overlap between the two date-ranges established for the probable manufacture of these artefacts. This does preclude the possibility that they were deposited together, as the date-ranges are ‘best estimates’. It is also possible that the discoidal knife may have been a curated heirloom (effectively a late Neolithic antique) that was deposited long after it was made, but this seems less likely than the prospect that they were discarded or deposited during different events that were probably separated by several centuries.

3.2 Context Although the axe has a chipped cutting edge it is still intact and would still have been an efficient tool at the time of deposition. While it is possible to explain its presence close to Pear Tree Farm merely as some form of casual disposal at the end of its useful life, it is now accepted that such functional interpretations are very over simplistic (Thomas 1999). While it cannot be established beyond doubt, the wealth of evidence for ritual activity along this section of the Witham valley suggests that the axe was a deliberate deposit. Analysis of spatial data collected from the Thames Valley indicates that there is significant correlation between the wetland localities where Neolithic axes and later prehistoric metalwork have been found (ibid, 85). Consequently, it seems unsurprising that the axe was recovered c. 600m to the south-west of the late Bronze Age site at Washingborough Pumping Station or c. 1300m west-south-west of the Iron Age causeway at Fiskerton. However, these spatial relationships may be misleading, as the majority of the Witham floodplain would have been dry land until the middle or late Bronze Age. This is amply illustrated by the fact that a large number of funerary monuments were constructed along both sides of the floodplain prior to the late Bronze Age. The most obvious and possibly most prolific of these monuments were several round barrow cemeteries. The largest and most extensive round barrow cemetery occupied large parts of what are now Washingborough Fen and Heighington Fen (SMR No. 60327). There are at least 30 barrows in this complex, which extends for 1.7km along the river valley, and the two most westerly barrows are located less than 350m east of where the axe and the discoidal knife were found. The barrows in this area have only been identified since the mid-20th century due to the desiccation and shrinkage of overlying peat deposits. Consequently, it is possible that there may be further undiscovered round barrows, some of which may be located to the north of Pear Tree Farm. Although there is a common perception that both round barrows and single inhumation burials with grave-goods are both early Bronze Age phenomena, these practices were actually initiated in the earlier Neolithic (Thomas 1999, 151). While the largest known concentration of Neolithic round barrows occurs in the Yorkshire Wolds, the fact that none of the barrows within the Witham valley have ever been excavated means that the chronological development of these monument complexes is not known. It is therefore possible that a significant number of the round barrows were created prior to the early Bronze Age. This in turn could mean that the axe from Pear Tree Farm formed part of a funerary deposit either placed within a round barrow or in a later Neolithic single grave situated within this funerary landscape. With this in mind, it should also be noted that discoidal knives are most commonly recovered from burial contexts. Given the probable difference in age between the two objects considered in this report, it seems possible, if not probable, that these items were placed in two different graves lying at or toward the western edge of the Washingborough Fen barrow cemetery. 4.0 Bibliography Butler, C. 2005 Prehistoric Flintwork. Stroud, Tempus Clark, J.D.G.1960 Excavations at the Neolithic site at Hurst Fen, Mildenhall, Suffolk. Proceedings of the Prehistoric Society, 26: 202-245. Garwood, P. 1999 Grooved Ware in Southern Britain: chronology and interpretation. In R. Cleal & A. MacSween (eds.) Grooved Ware in Britain and Ireland. Neolithic Studies Group Seminar Papers, 3: 145-176. Parker-Pearson, M. 1993 Bronze Age Britain. London, Batsford Thomas, J. 1999 Understanding The Neolithic. London, Routledge |

||||||||

v.4 'Rise of the Screen' |